Assoc. Prof. Ivan I. Lesov, Ph.D.

Interests

- Emulsions - Prep., Stability & Application

- Surfactant- and Particle-Stabilized Foams

- Bulk Rheology of Emulsions, Suspensions and Foams

- Foamed Ceramics

- Cosmetics

Bio

Dr. Ivan Lesov became an Associate Professor in May, 2025. He earned his PhD in Physical Chemistry (2014) from Sofia University and has extensive experience in academic and industrial research. He was awarded a 1-year SCIEX NMS research fellowship grant at ETH Zurich (2014–2015) and has conducted research as a guest at Saint-Gobain Research (Paris 2011, 2013, 2014), ETH Zurich (2017), and Cambridge University (2017). Over the course of his career, he has contributed to more than 29 academic and industrial projects with multinational partners such as Saint-Gobain Research, PepsiCo, Unilever, and BASF. Dr. Lesov also served as Head of the Laboratory for Technology and Product Development (2019–2023) in the Competence Center for “Sustainable Utilization of Bio-Resources and Waste of Medicinal and Aromatic Plants for Innovative Bioactive Products (BG05M2OP001-1.002-0012).” Since 2022, he has been a member of the Bulgarian Association of Cosmetologists (BAC) and the International Federation of Societies of Cosmetic Chemists (IFSCC).

His research focuses on the development and application of advanced materials, including porous ceramics, polymeric particles and foams, as well as innovative methods for emulsification and improving process efficiency. Dr. Lesov is the author or co-author of 18 peer-reviewed publications with 600+ citations (h-index = 11) and is a co-inventor of 2 granted international patents. Dr. Lesov received the Sofia University award for Best Young Scientist of the Sofia University in 2019.

Dr. Lesov leads practical exercises in Transport Phenomena, Rheology of dispersions, Colloidal Dispersions (Preparation, Stability, and Applications), and Cosmetic Formulations, as well as delivers lectures on Separation Processes in Dispersions (2023-onward). He has been actively involved in the development, continuous improvement, and compilation of study materials for these courses, ensuring their relevance and quality, while also mentoring 3 MSc and 1 BSc students throughout the preparation of their theses.

Publications

Most recent publications

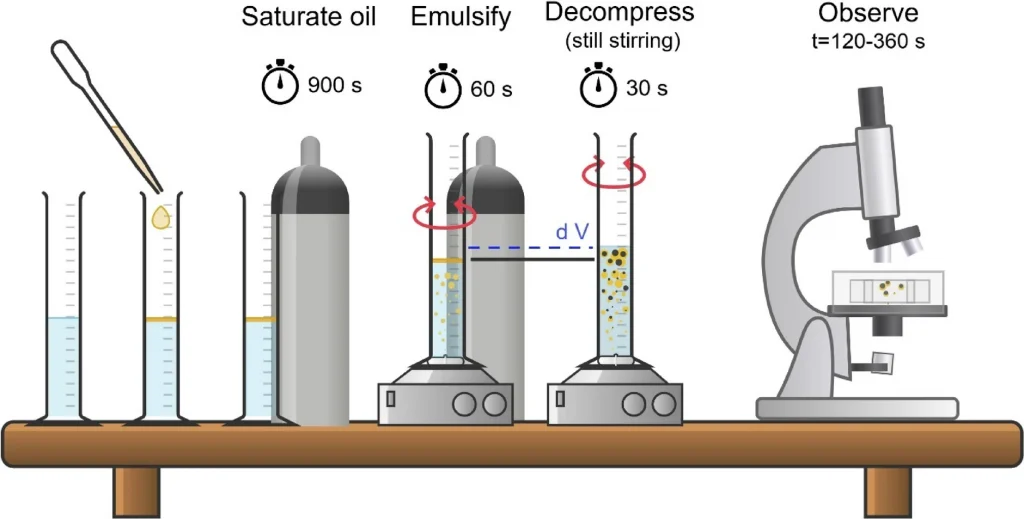

Bubbles nucleation in supersaturated emulsion drops

Bubble nucleation plays a significant role in applications ranging from food and beverages to cosmetics, polymer foams, and advanced porous materials. While extensively studied in homogeneous solutions and particle suspensions, bubble nucleation mechanisms in heterophasic liquid dispersion, such as emulsions, are less understood. This study hypothesizes that tuning physicochemical and mixing hydrodynamics allows design over the bubble nucleation and growth under mild gas supersaturations. Supersaturated oils were emulsified under mild stirring, followed by rapid decompression to trigger nucleation. The process was analyzed by monitoring changes in emulsion volume and optical microscope observations. Key parameters such as gas saturation pressure, viscosities of the continuous and dispersed phases, gas solubility and dissolution kinetics, and mixing intensity were systematically varied. Bubble nucleation occurs mainly via a heterogeneous mechanism, accelerated by shear and gas migration kinetics. Increased oil phase viscosity enhanced bubble formation and retention in droplets, while higher aqueous phase viscosity suppressed nucleation in the continuous phase. The number and size of the obtained bubbles varied significantly, depending on the phase of nucleation origin and the physicochemical conditions. This study reveals pathways to optimize bubble nucleation and initial growth dynamics, which can be used for optimization of pore size distribution of emulsion-based materials.

Cosmetic potential of haberlea rhodopensis extracts and extracellular vesicles in human fibroblast cells

Skin ageing is a complex biological process influenced by cellular senescence, oxidative stress, and extracellular matrix degradation. Emerging evidence suggests that plant-derived bioactive compounds and extracellular vesicles (EVs) play a crucial role in modulating cellular homeostasis, promoting tissue regeneration, and counteracting age-related morphological and functional changes. This study investigates the impact of Haberlea rhodopensis in vitro culture extracts, native and enriched with EVs, on key cellular processes, including morphology, mitochondrial dynamics, lysosomal activity, gene expression, and genotoxicity in human dermal fibroblasts. The extracellular vesicles were identified in terms of shape, size, and morphology using dynamic light scattering, negative staining and observation under a transmission electron microscope. A comprehensive in vitro analysis was conducted utilizing light microscopy to assess cellular morphology and lysosomal mass, fluorescence microscopy for actin cytoskeletal organization, mitochondrial integrity, and nuclear morphology, and gene expression profiling for markers associated with collagen synthesis (COL1A1, COL3A1), senescence (CDKN1A), and oxidative stress response (NFE2L2). Additionally, cell cycle progression was evaluated, and genotoxicity was assessed using the neutral comet assay. Haberlea rhodopensis in vitro culture extracts and EVs were found to preserve fibroblast morphology, enhance mitochondrial mass, and upregulate collagen-related gene expression. These effects were concentration-dependent. The extracts exhibited biocompatibility with minimal genotoxic effects, indicating their potential as safe bioactive agents for skin rejuvenation. The findings suggest that Haberlea rhodopensis in vitro culture extracts and their enrichment with extracellular vesicles hold promise for cosmetic and dermatological applications, particularly in enhancing collagen production, preserving cellular integrity, and mitigating age-related alterations in skin fibroblasts. Further studies are warranted to elucidate the underlying molecular mechanisms and optimize formulation strategies for clinical translation.

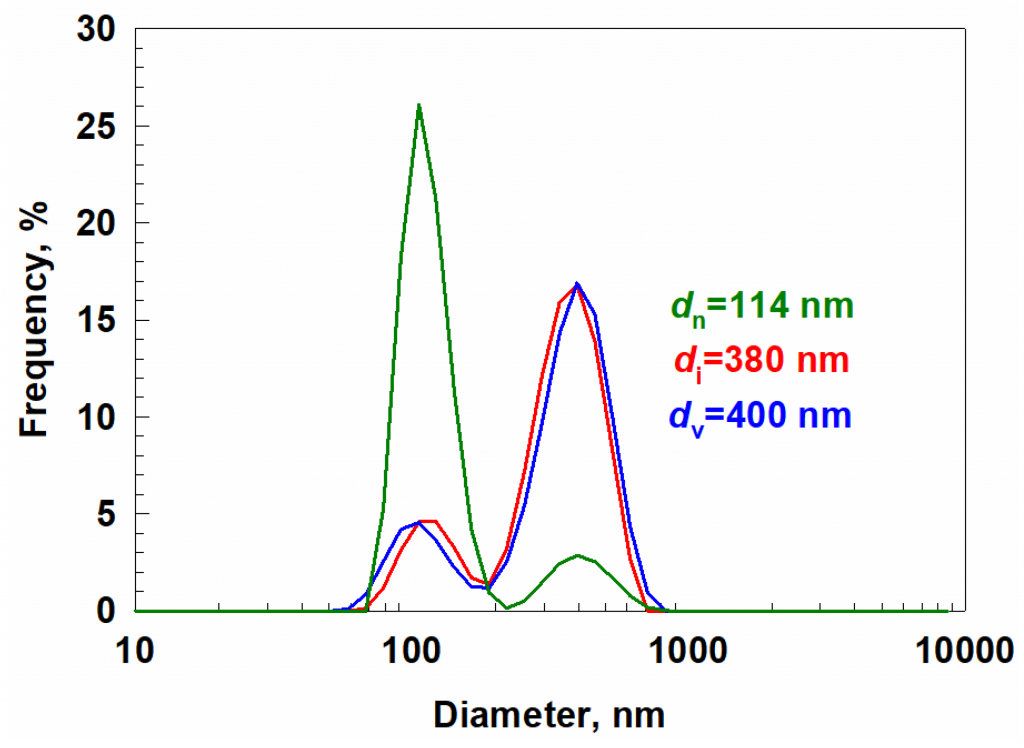

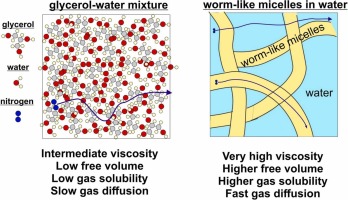

Role of dispersion nanostructure for bubble dissolution under pressure

Understanding the factors that affect bubble dissolution under pressure is crucial for the pneumatic transport of dispersions. This study probes the kinetics of air dissolution, the air solubility at a given pressure, and the gas diffusion due to bubble dissolution to elucidate the molecular mechanisms of gas transport in liquid dispersions with varied structures and viscosities. We achieve our aims by using water-glycerol mixtures, silicone oils with different viscosities, surfactant solutions containing worm-like micelles and having different macroscopic viscosities, particle suspensions, and surfactant solutions capable of forming a condensed adsorption layer on the bubble surfaces at ambient conditions. The results show that the dissolution rate does not depend on the macroscopic viscosity for silicone oils and solutions containing worm-like micelles, indicating that gas diffusion occurs faster than the movement of big polymeric molecules and worm-like micelles. We could predict the experimentally determined diffusion coefficients by accounting for free volume in these media and using the equation for Knudsen diffusion. We show that one way to decrease the rate of bubble dissolution under pressure is to add surfactants, which can decrease the permeability of the adsorption layer formed on the bubble surface by forming a condensed adsorption layer.

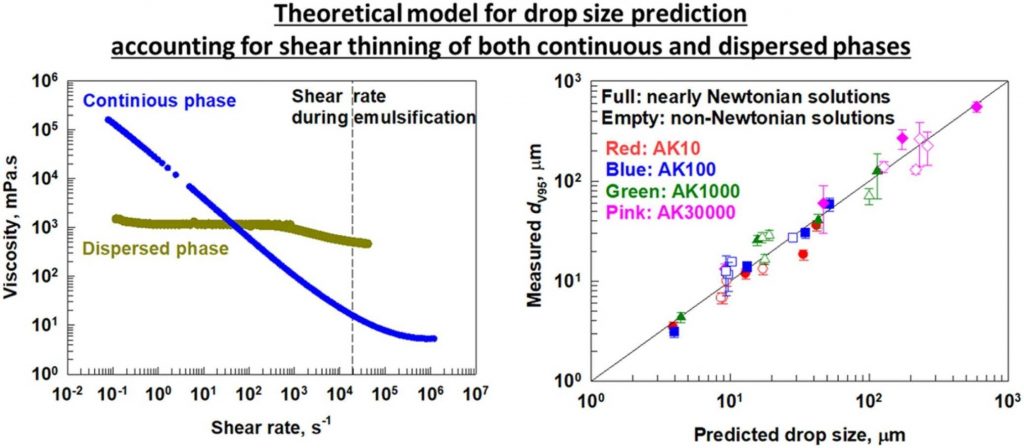

Emulsification in nearly Newtonian and non-Newtonian media of wormlike micelles

Emulsification experiments with four silicone oils, having viscosities ranging from 0.01 to 30 Pa.s, were conducted in two types of media: nearly Newtonian polyvinyl alcohol (PVA) solutions and non-Newtonian mixtures induced by worm-like micelles in solutions of sodium laureth sulfate and cocoamidopropyl betaine (BS) with NaCl. The increased viscosity of BS solutions upon the addition of NaCl did not significantly affect the drop size in the formed emulsions. In contrast, the increased viscosity of solutions with higher PVA concentrations significantly reduced the drop sizes for all silicone oils. A theoretical expression predicting the maximum drop size in both types of media (nearly Newtonian and non-Newtonian) was derived and validated against experimental data. The expression accounts for shear-thinning behavior in both the aqueous and oil phases. Interfacial stress dominates the breakage of less viscous oils, while viscous stress inside the breaking drop plays a leading role for more viscous oils. The formation of emulsions with similar sizes in non-Newtonian solutions of BS with different NaCl concentrations was explained by their strongly shear-thinning behavior, which leads to nearly similar viscosity at high shear rates, despite their zero-shear viscosities differing by more than two orders of magnitude.

Role of particle size on the cohesive strength of non-sintered (green) ceramics

Preparation of particle-loaded foams, followed by drying, sintering and/or cross-linking are widely explored routes for developing lightweight ceramics with high mechanical strength. The non-sintered dry ceramic foams are less studied due to their intricate production and the assumed poor mechanical strength of the obtained “green” materials. Here we produce lightweight ceramics from foamed particle suspensions containing spherical silica particles with radii varied between 4.5 nm and 7 µm. The wet foams are prepared in the presence of cationic surfactant and were dried at ambient conditions to obtain porous materials with mass densities between 100 and 700 kg/m3. The materials containing smaller particles exhibited much higher strength (by up to 2000 times), approaching that of the sintered materials. A new theoretical expression for predicting the mechanical strength of such materials is derived and is used to explain the measured strengths of the produced materials through the van der Waals attraction between the particles in the final dry materials.

ceramics-1024x410.jpg)